Shakers

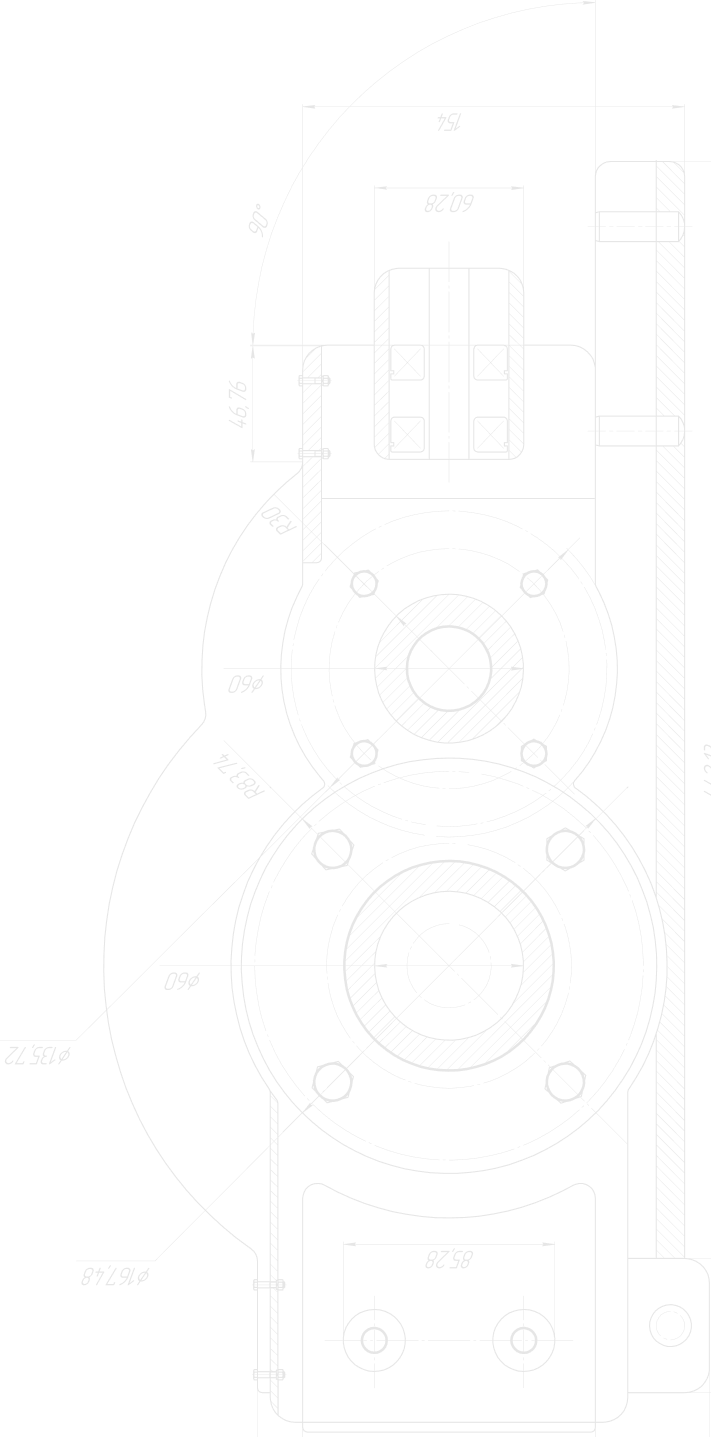

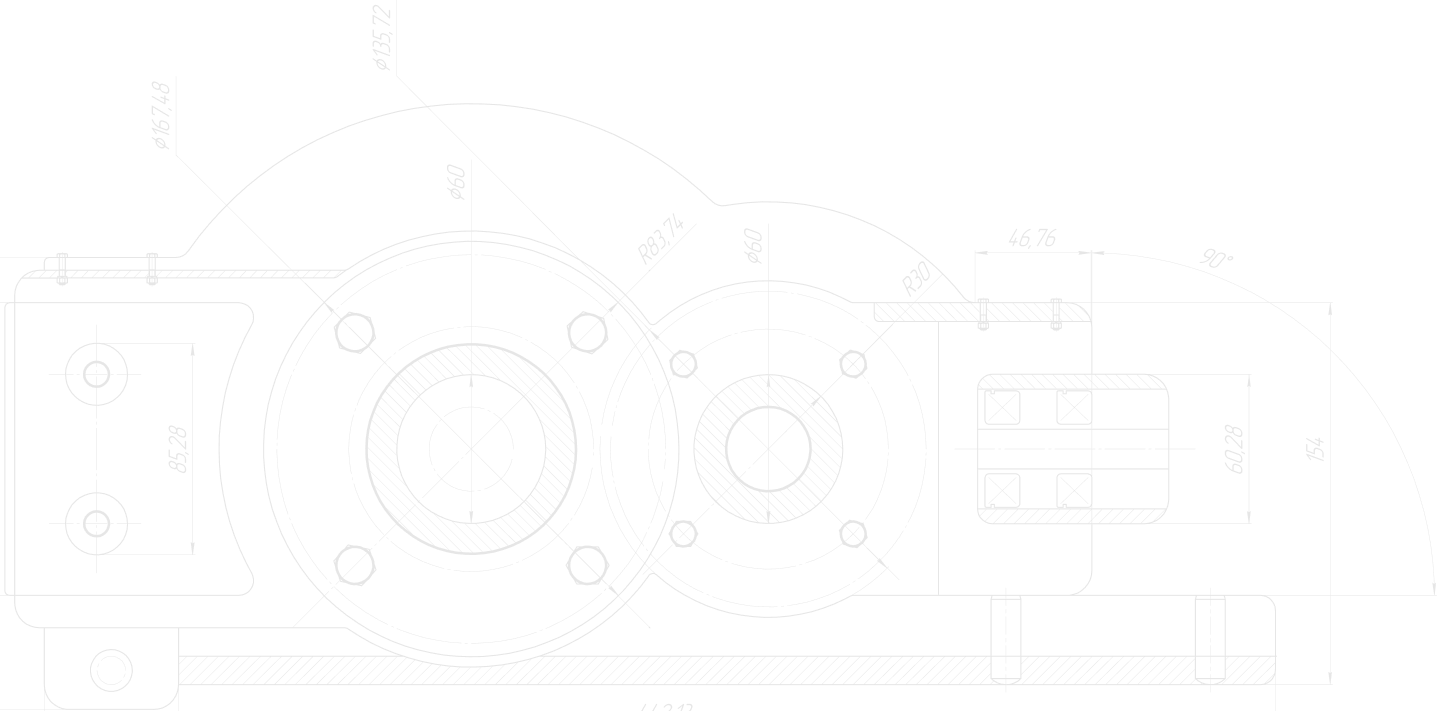

Our robustly built vibrators are designed to shake shafts up to 600 mm in diameter and of varying heights.

They have been manufactured for 20 years, which is a guarantee of quality and after-sales service.

The range is constantly expanding, from economical models for small areas to more advanced models that can shake up to 300 trees per hour.

Discover our machines